Slitting Cutters

Rotary Slitter Knives Maxwell manufactures slitter knives for all machine types: Maxwell manufactures slitter knives for all machine types: Adherence to the smallest possible thickness tolerance down to ± 2 microns. Subdivision of thickness tolerance in 3 areas (-,...

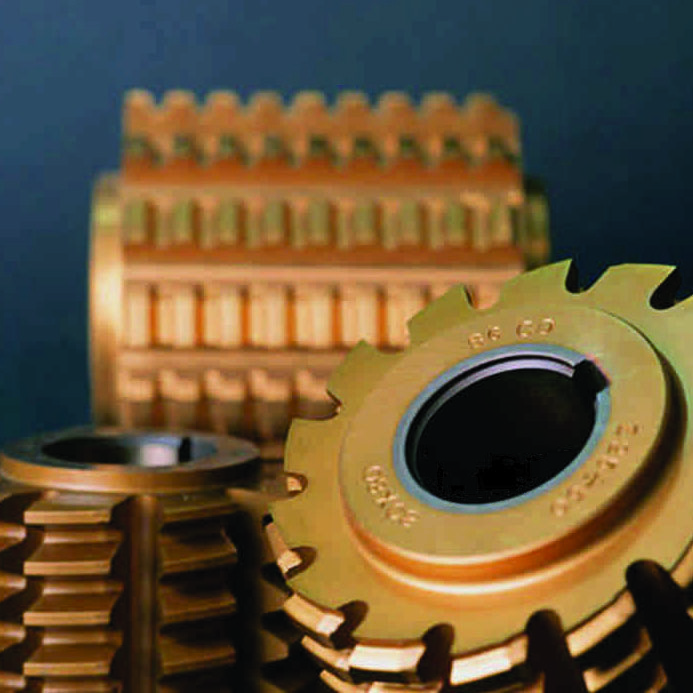

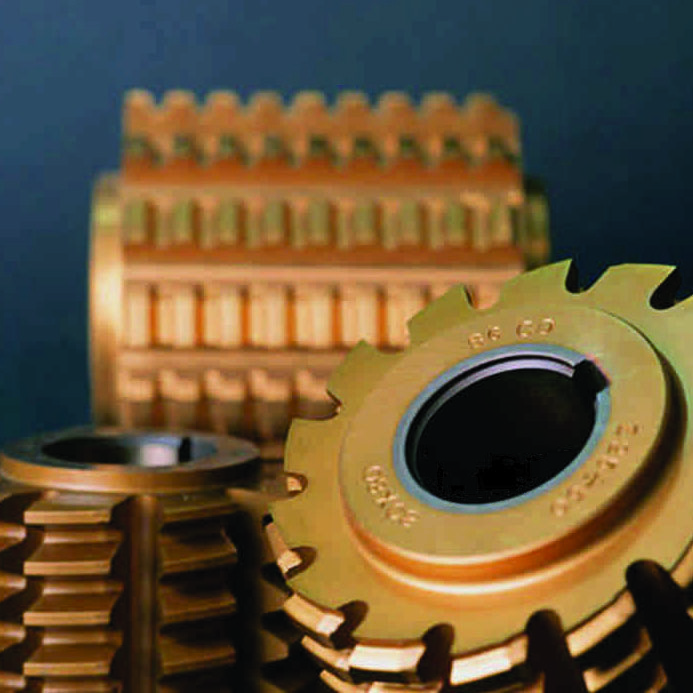

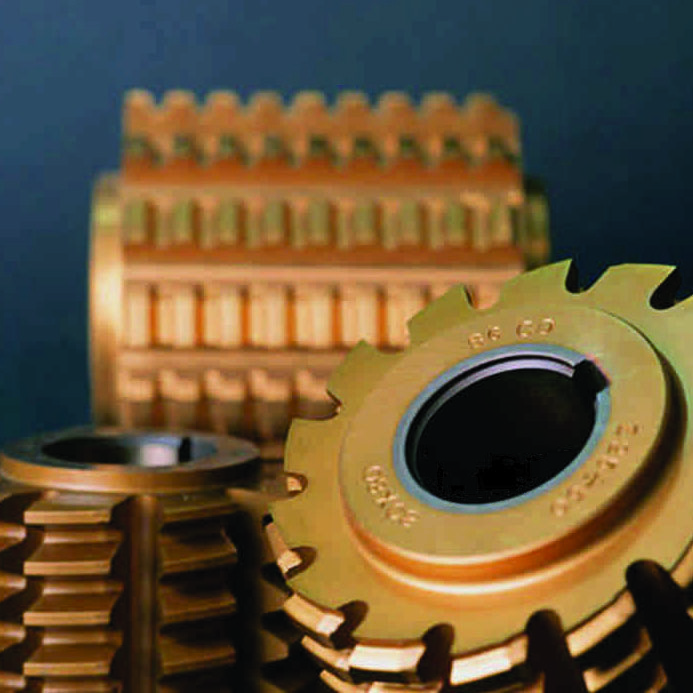

Hacksaw/Bandsaw Milling Cutters

Hacksaw milling cutters produced in high speed steels in a wide variety of diameters and lengths according to the application and machine. Our cutters are utilised to machine all types of bandsaw forms including vari-pitch, hook and positive rake. We produce hacksaw...

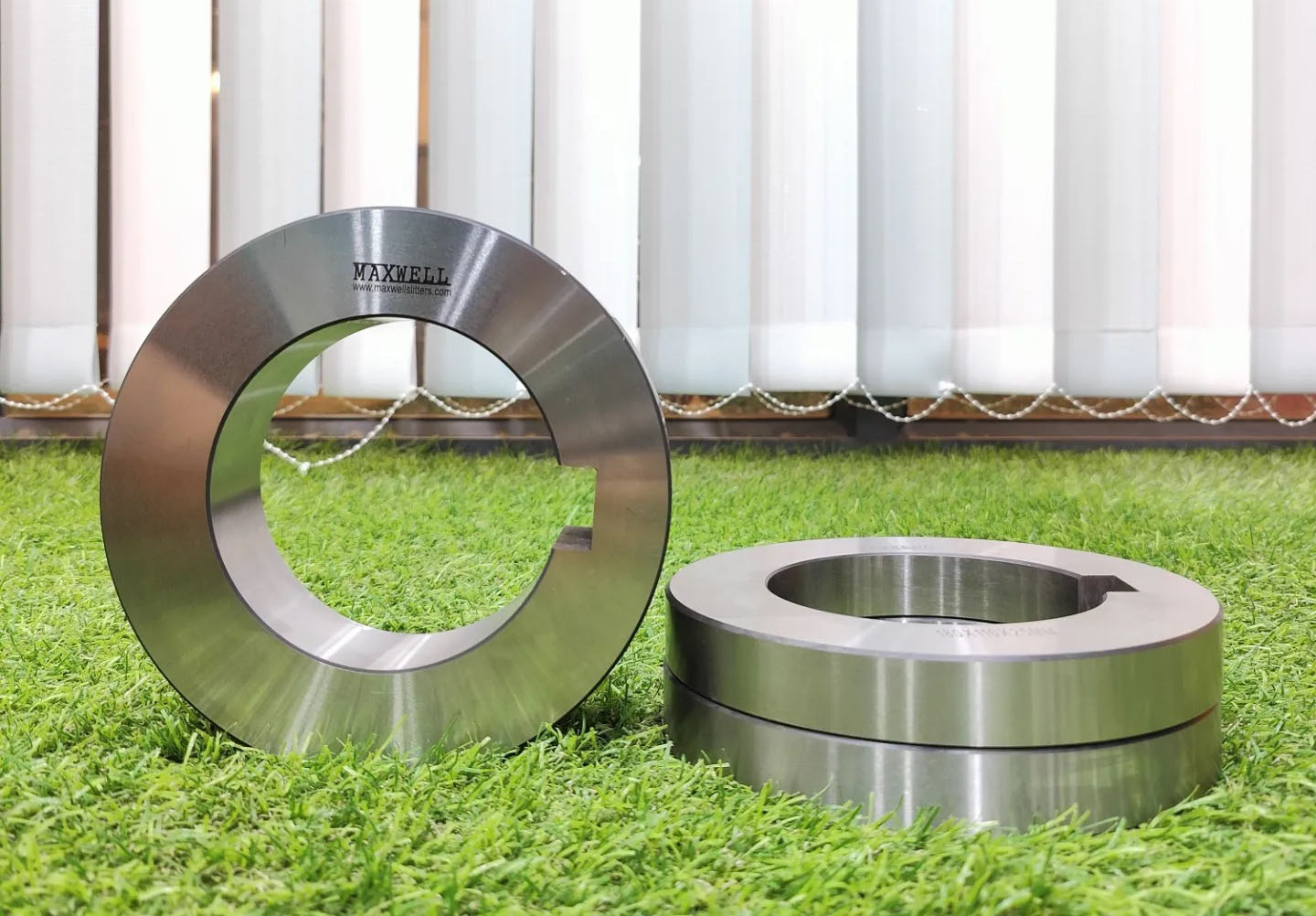

Slitter Spacers

Maxwell Slitting Line Spacers (Metallic & Rubberized) We manufacture a wide range of slitting line spacers (Metallic and Rubberized). These slitting spacers are widely used in different industries for cutting and trimming of different metals and alloys. We...

Shaving Cutters

After hob or shaper cutter processing, shaving cutters are used to remove very small portions of the gear tooth surface. After hob or shaper cutter processingGear Shaving operation fixes errors in the index, helical angle, tooth shape, and eccentricity. Additionally,...

Broaching

Broaching is a machining process that removes material with a toothed tool called a broach. Broaching is classified into two types: linear and rotary. The broach is run linearly against the surface of the workpiece to produce the cut in linear broaching, which is the...

Shaving Cutters

After hob or shaper cutter processing, shaving cutters are used to remove very small portions of the gear tooth surface. After hob or shaper cutter processingGear Shaving operation fixes errors in the index, helical angle, tooth shape, and eccentricity. Additionally,...

Broaching

Broaching is a machining process that removes material with a toothed tool called a broach. Broaching is classified into two types: linear and rotary. The broach is run linearly against the surface of the workpiece to produce the cut in linear broaching, which is the...

Cylindrical/Scalping Cutter

Product Code : MXSCA 18

Involute Gear Cutters

Product Code : MXIGC 14

Material : HSS M2;M35;ASP 2030

Metal Slitting Saw

Product Code: MXMSS 19

PayPal – The safer, easier way to pay online!

Gear Shaving Cutters

Product Code : MXGSC 16

PayPal – The safer, easier way to pay online!

Gear Hobs

Product Code: MXIGH 01

Material : HSS M2;M35;M42;ASP 30 & 60

Center Drills

Model / Type Available Double ended tool for centering prior to drilling or for producing a countersink from, for lathe centre location. Suitable for both hand and machine use.

Hacksaw/Bandsaw Milling Cutters

Hacksaw milling cutters produced in high speed steels in a wide variety of diameters and lengths according to the application and machine. Our cutters are utilised to machine all types of bandsaw forms including vari-pitch, hook and positive rake. We produce hacksaw...

Slitter Spacers

Maxwell Slitting Line Spacers (Metallic & Rubberized) We manufacture a wide range of slitting line spacers (Metallic and Rubberized). These slitting spacers are widely used in different industries for cutting and trimming of different metals and alloys. We...

Shaving Cutters

After hob or shaper cutter processing, shaving cutters are used to remove very small portions of the gear tooth surface. After hob or shaper cutter processingGear Shaving operation fixes errors in the index, helical angle, tooth shape, and eccentricity. Additionally,...

Broaching

Broaching is a machining process that removes material with a toothed tool called a broach. Broaching is classified into two types: linear and rotary. The broach is run linearly against the surface of the workpiece to produce the cut in linear broaching, which is the...

Cylindrical/Scalping Cutter

Product Code : MXSCA 18

Involute Gear Cutters

Product Code : MXIGC 14

Material : HSS M2;M35;ASP 2030

Broaching

Broaching is a machining process that removes material with a toothed tool called a broach. Broaching is classified into two types: linear and rotary. The broach is run linearly against the surface of the workpiece to produce the cut in linear broaching, which is the...

Cylindrical/Scalping Cutter

Product Code : MXSCA 18

Involute Gear Cutters

Product Code : MXIGC 14

Material : HSS M2;M35;ASP 2030

Metal Slitting Saw

Product Code: MXMSS 19

PayPal – The safer, easier way to pay online!

Gear Shaving Cutters

Product Code : MXGSC 16

PayPal – The safer, easier way to pay online!

Gear Hobs

Product Code: MXIGH 01

Material : HSS M2;M35;M42;ASP 30 & 60

Center Drills

Model / Type Available Double ended tool for centering prior to drilling or for producing a countersink from, for lathe centre location. Suitable for both hand and machine use.

Side Milling Cutters

Product Code: MXSMC 04

Material : HSS M2;M35;ASP 2030

Tool Bits

Product Code: MXTB 23

Shaving Cutters

After hob or shaper cutter processing, shaving cutters are used to remove very small portions of the gear tooth surface. After hob or shaper cutter processingGear Shaving operation fixes errors in the index, helical angle, tooth shape, and eccentricity. Additionally,...

Broaching

Broaching is a machining process that removes material with a toothed tool called a broach. Broaching is classified into two types: linear and rotary. The broach is run linearly against the surface of the workpiece to produce the cut in linear broaching, which is the...

Cylindrical/Scalping Cutter

Product Code : MXSCA 18

Involute Gear Cutters

Product Code : MXIGC 14

Material : HSS M2;M35;ASP 2030

Metal Slitting Saw

Product Code: MXMSS 19

PayPal – The safer, easier way to pay online!

Gear Shaving Cutters

Product Code : MXGSC 16

PayPal – The safer, easier way to pay online!

Gear Hobs

Product Code: MXIGH 01

Material : HSS M2;M35;M42;ASP 30 & 60

Center Drills

Model / Type Available Double ended tool for centering prior to drilling or for producing a countersink from, for lathe centre location. Suitable for both hand and machine use.

Cylindrical/Scalping Cutter

Product Code : MXSCA 18

Involute Gear Cutters

Product Code : MXIGC 14

Material : HSS M2;M35;ASP 2030

Metal Slitting Saw

Product Code: MXMSS 19

PayPal – The safer, easier way to pay online!

Gear Shaving Cutters

Product Code : MXGSC 16

PayPal – The safer, easier way to pay online!

Gear Hobs

Product Code: MXIGH 01

Material : HSS M2;M35;M42;ASP 30 & 60

Center Drills

Model / Type Available Double ended tool for centering prior to drilling or for producing a countersink from, for lathe centre location. Suitable for both hand and machine use.

Side Milling Cutters

Product Code: MXSMC 04

Material : HSS M2;M35;ASP 2030

Tool Bits

Product Code: MXTB 23

Broaches

Product Code: MXCMC 07

Material : HSS M2;M35;ASP 2030

Cylindrical Milling Cutter

Product Code: MXPMC 03

Material : HSS M2;M35;ASP 2030