Maxwell Gear Shaving Cutters are ground precisely to be used for finishing gears that are pre-shaped or pre-hobbled. Because of the delicate nature of these tools, they are supplied with lead test charts and inspection. They come in three major types: –

- Conventional gear shaving cutters

- Diagonal gear shaving cutters

- Underpass gear shaving cutters

The other types include the plunge, transverse, internal/external shaving and underground as well as finished shaving cutters. These models are not popular and are mainly supplied on order. Their range can be expressed in two broad senses. One range comes in two sets that are 30-3 DP and 0.8-8 Module. The other range is the 170mm to 260mm PCD.

Types

Conventional, diagonal & underpass

Range

0.8-8 Module and 30-3 DP

170 mm to 260 mm PCD.

Profiles

Standard Involute, Tip Relief, Profile and Lead Crowning, Special profiles as per customer’s requirement.

Material

HSS M2;M35;ASP 2030

Beyond gear shaving cutters Maxwell Tools offer a host of other services. They include: –

- Advice- this is aimed at answering any query you might have regarding gear cutters or related services. Inquiry is made online through a customer friendly portal. You may also call the office through a hotline that is provided on the web. Your questions will be answered by resourceful technicians who understand cutters and your work environment. They will assist you to maximize production within any environment. The technicians will also offer useful tips on how to increase efficiency and ensure that your tools last long.

- Inspection- technicians at Maxwell Tools conduct thorough inspection of all units during the production and after production. This is aimed at ensuring that consistency is achieved especially when the cutters are produced in large quantities. The inspection team understands quality standards for the industry and will ensure that they are met.

- Gear Cutter Repair- Maxwell Tools allows clients to ship cutters that fail so that they are repaired. A highly skilled and experienced team will explain the options available in each case. This allows you to make an informed decision. In some instances new models or units will be proposed. All the charges will be revealed to facilitate planning.

Maxwell Tools has the manpower and machines to deliver customized tools. This includes computer software for generating profiles for each tool that a client orders. The engineers simulate the tools to give you an idea of what to expect. This process ensures that the highest level of precision is achieved once the units are produced. Computerized production process raises the degree of consistency from one piece to the other. This consistency will be transferred to your production process.

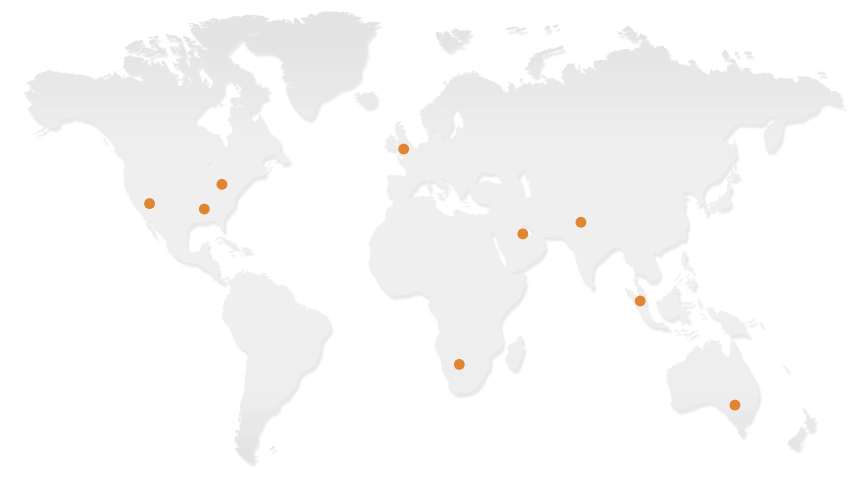

The materials used in manufacturing the cutters are sourced from reputable global suppliers. They are tested for high quality and prepared using the latest technology with the aim of achieving the highest level of purity. High quality material results in reliable tools that are durable. They are less prone to wear and perform excellently in conditions of extreme heat.

The process of ordering gears is simplified through the provision of an interactive and resourceful online portal. It gives images and a detailed description of each unit. This makes it easy to select the right tool for your work. You will enjoy the most exciting shopping experience and excellent value for money.