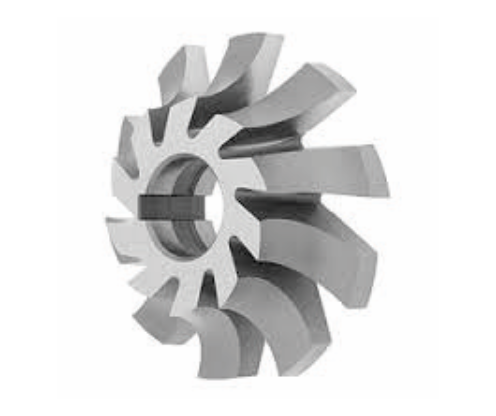

High Precision Milling Cutters

Maxwell is one of the leading manufacturers of milling cutters worldwide. We specialize in the use of High-speed steel of various grades and advanced technology for heat treatment ensuring the right recipe for your industrial use.

High Precision Cutting Tools

Maxwell is one of the leading manufacturers of milling cutters worldwide. We specialize in the use of High-speed steel of various grades and advanced technology for heat treatment ensuring the right recipe for your industrial use.

QUALITY & EXCELLENCE

Every product is trialed & tested so you only get the best of the best.

Gear Hobs

woodruff keyseat

Gear Cutters

SERRATION CUTTERS

Material : HSS M2;M35;ASP 2030

Maxwell Serration Cutters are made from the highest quality raw materials available in the market. They are best suited for clamping surface. The common industries using these cutters include agriculture and automation. Their fine tooth features enable them to produce smooth cuts on all surfaces.

Ordering Instructions : Diameter ; Pitch, Length, Bore

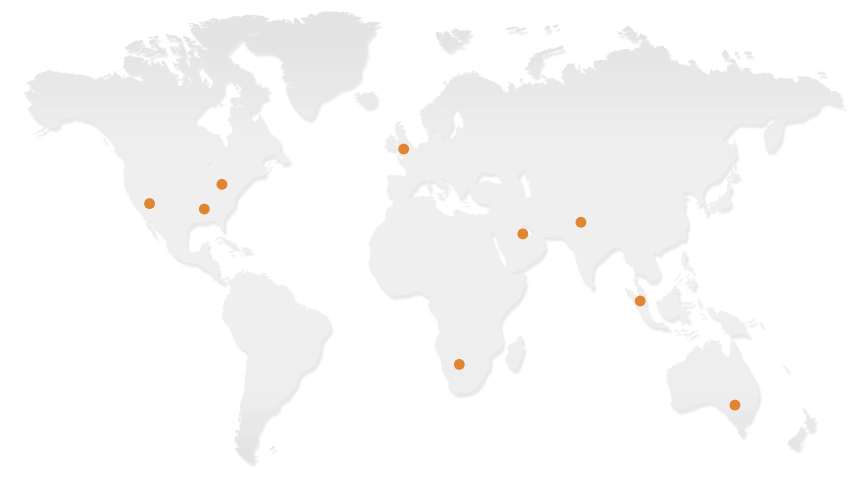

Our Products

Leading manufacturer of gear cutting tools in India

BROACHES

Maxwell manufactures both standard and special

CONCAVE CUTTERS

Used to produce true convex radius. These cutters

SPROCKET CUTTERS

Sprocket milling cutters are also referred to as Rotary

CONVEX CUTTER

To carve out the true concave radius. These

CORNER ROUNDING CUTTERS

Corner rounding milling cutters are designed for

SIDE & FACE CUTTERS

The Maxwell Side Face is distinguished by the

Our Services

GEAR CUTTER INSPECTIONS

GEAR CUTTER REPAIRS

COMPLAINTS

Let’s Work Together

To request a proposal , please fill the form below and we will get back to you with in 24 hours

15k + Products

Manufactured