Definition

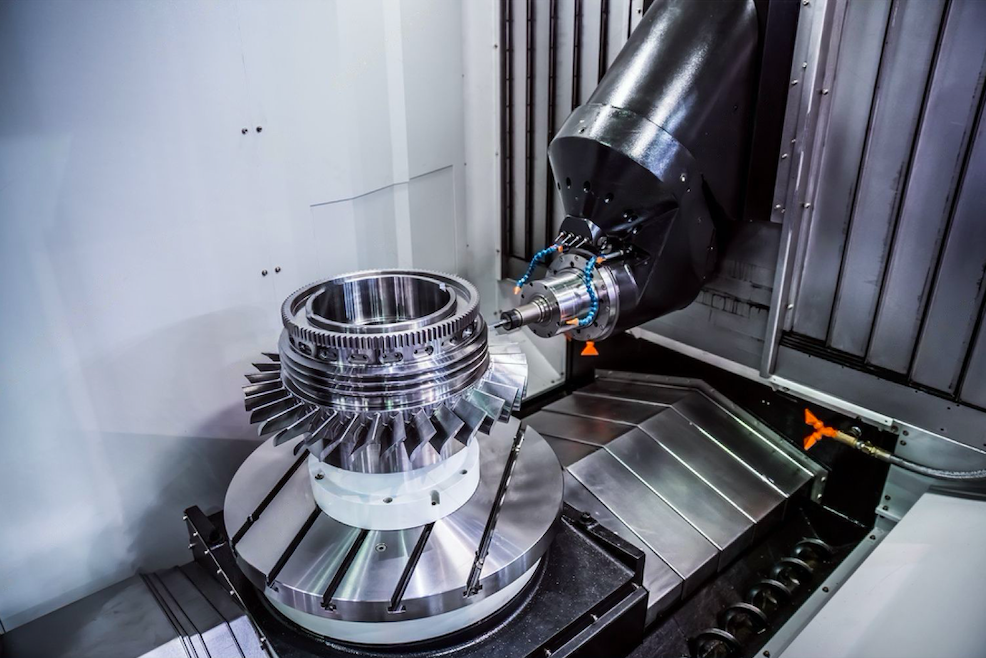

The workpiece is fed past a spinning multipoint cutter on a milling machine, which removes material from the workpiece. Due to the cutter’s high speed and numerous cutting blades, the rate of metal removal is significantly higher. The fact that almost all operations can be carried out on it with high accuracy makes it the most significant machine in the tool room.

Application of a Milling Machine:

A Milling Machine is used to machine flat surfaces, slots, and contoured surfaces. Additionally, it can be used to create complex and uneven surfaces, revolution surfaces, gear cutting, and internal and external thread machining. Machining helical surfaces with different cross-sections, among other things.

Operations of a milling machine

A milling machine can carry out the following operations:

- Face Milling Operation

- End Milling Operation

- Plain or Slab Milling Operation

- Gang Milling Operation

- Gear Milling Operation

- Side Milling Operation

- T-Slot Milling Operation

Advantages of Milling Machine:

Superior surface finish: The milling machine’s multi-cutting edges provide the materials’ surfaces with a better finish

High speed: Milling removes metal quickly because the cutter rotates quickly and has multiple cutting edges.

High Accuracy: The milling machine produces highly accurate goods, particularly when using the CNC machine, the most advanced type of milling machine.

Enhanced Productivity: CNC milling machines are ones that use software to control the milling process. It has improved accuracy and finish, increasing production overall.

Checkout our wide range of high-precision milling tools for your industry:

https://www.maxwelltools.com/products/