Involute Gear Cutters

Product Code : MXIGC 14

Material : HSS M2;M35;ASP 2030

Metal Slitting Saw

Product Code: MXMSS 19

PayPal – The safer, easier way to pay online!

Gear Shaving Cutters

Product Code : MXGSC 16

PayPal – The safer, easier way to pay online!

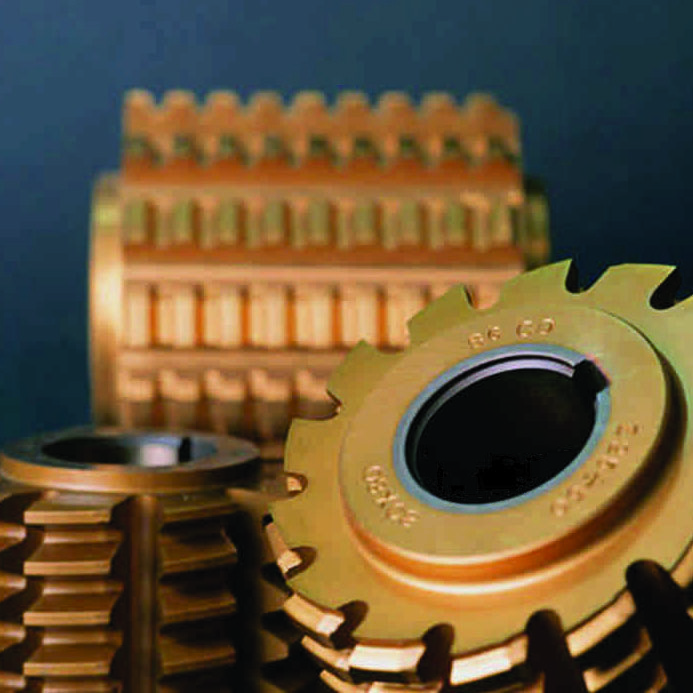

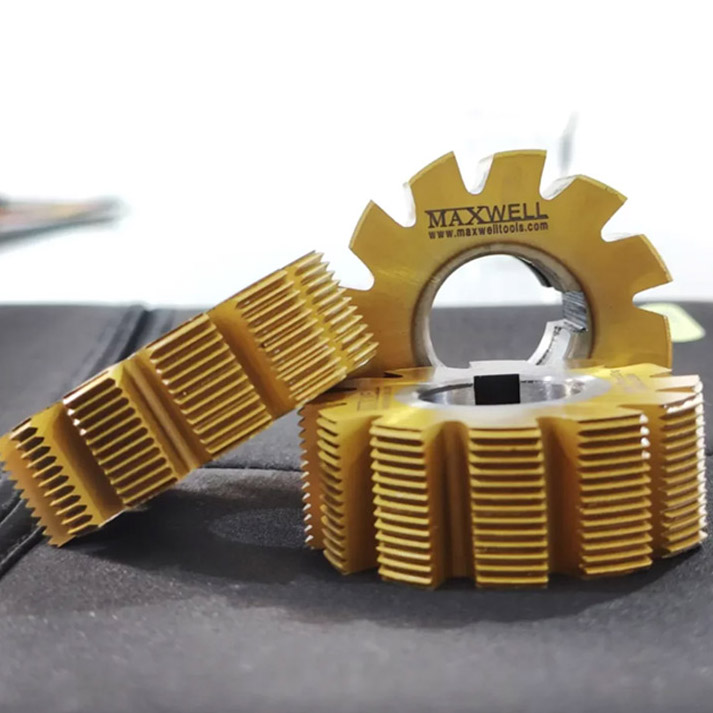

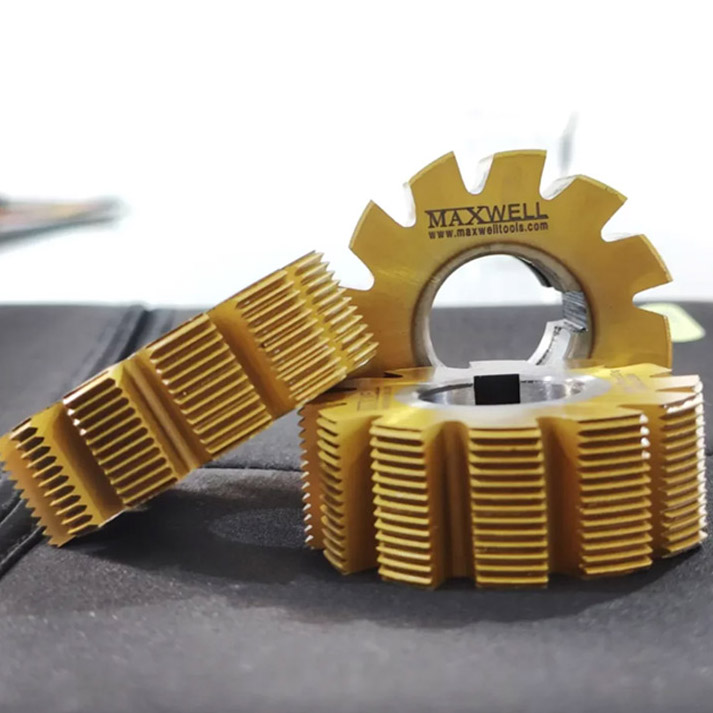

Gear Hobs

Product Code: MXIGH 01

Material : HSS M2;M35;M42;ASP 30 & 60

Center Drills

Model / Type Available Double ended tool for centering prior to drilling or for producing a countersink from, for lathe centre location. Suitable for both hand and machine use.

Dovetail Cutters

Product Code: MXCMC 12

Material : HSS M2;M35;ASP 2030

Serration Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

Circular Segmental Saws

We produce segmental circular saw blades in diameters from 250 mm to 1610 mm in various tooth profiles.

Hacksaw Milling Cutters

Product Code: MXHSMC 09

Material : HSS M2;M35;ASP 2030

Coatings available on request

End Mills Cutters

Product Code: MXCMC 11

Material : HSS M2;M35;ASP 2030

T-Slot Milling Cutters

Product Code: MXCMC 13

Material : HSS M2;M35;ASP 2030

Coatings available on request

Reamers

Product Code: MXR 22

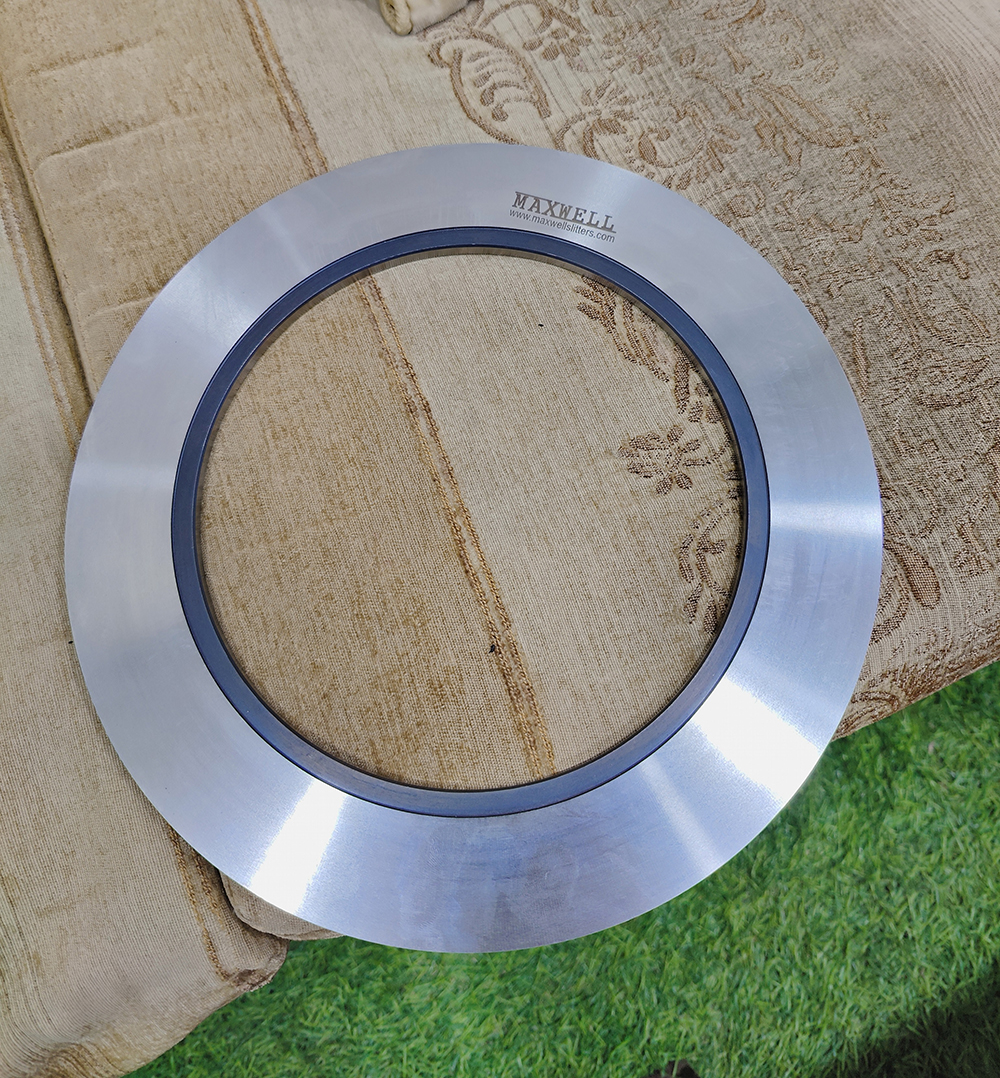

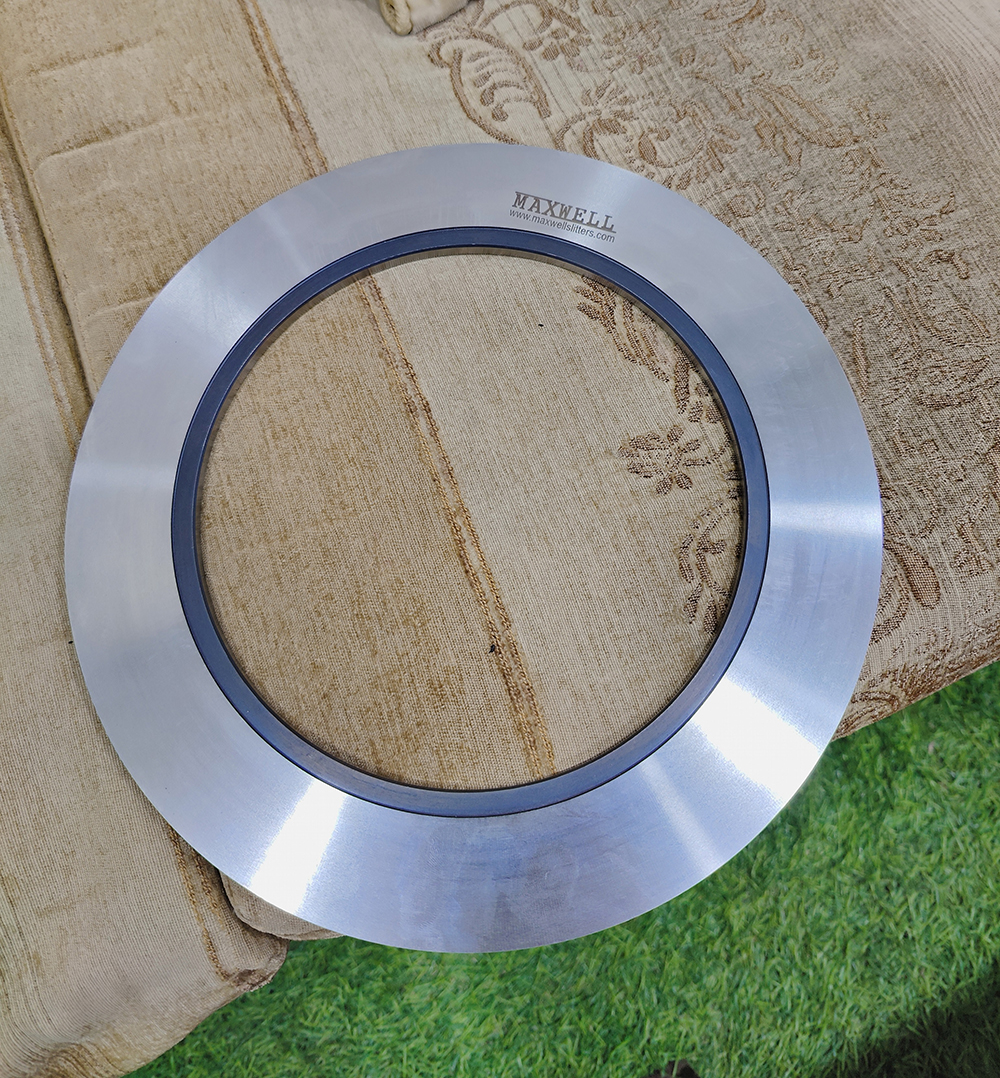

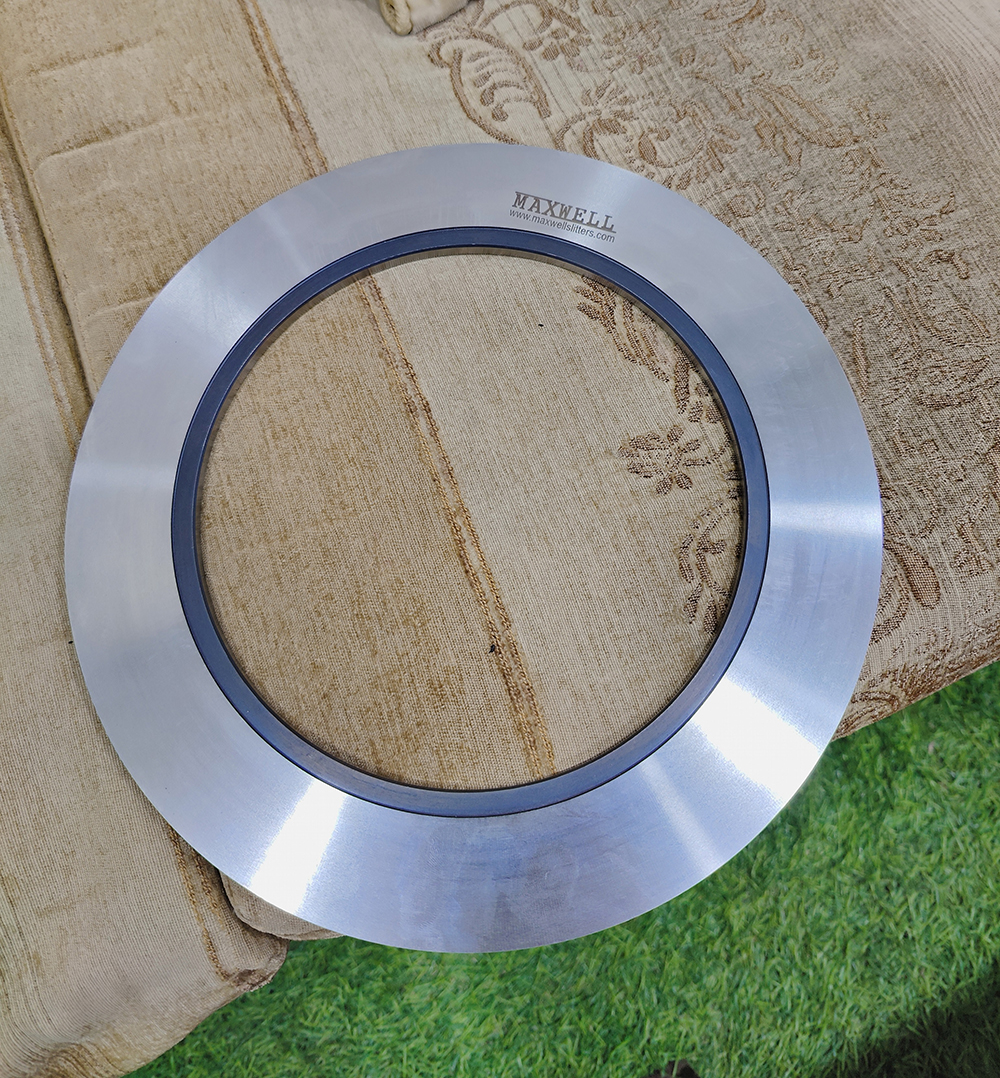

Slitter Cutters

Available in D2,D3,HSS,H11,H13

Gear Hobs

Product Code: MXIGH 01

Material : HSS M2;M35;M42;ASP 30 & 60

Center Drills

Model / Type Available Double ended tool for centering prior to drilling or for producing a countersink from, for lathe centre location. Suitable for both hand and machine use.

Tool Bits

Product Code: MXTB 23

Broaches

Product Code: MXCMC 07

Material : HSS M2;M35;ASP 2030

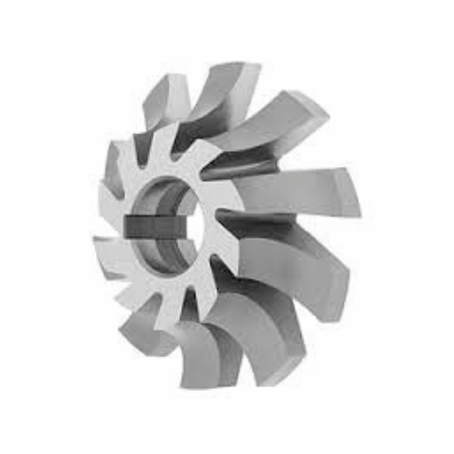

Cylindrical Milling Cutter

Product Code: MXPMC 03

Material : HSS M2;M35;ASP 2030

Paper Cutters

Product Code: MXPPC 20

Hacksaw Milling Cutters

Product Code: MXHSMC 09

Material : HSS M2;M35;ASP 2030

Coatings available on request

End Mills Cutters

Product Code: MXCMC 11

Material : HSS M2;M35;ASP 2030

T-Slot Milling Cutters

Product Code: MXCMC 13

Material : HSS M2;M35;ASP 2030

Coatings available on request

Reamers

Product Code: MXR 22

Slitter Cutters

Available in D2,D3,HSS,H11,H13

Shell End Mills

Product Code: MXCMC 08

Material : HSS M2;M35;ASP 2030

Coatings available on request

ANGLE MILLING CUTTERS

Product Code: MXCMC 07

Material : HSS M2;M35;ASP 2030

Side & Face Milling Cutters

Product Code : MXCMC 06

Material : HSS M2;M35;ASP 2030

Coatings available on request

CORNER ROUNDING CUTTERS

Product Code : MXCMC 06

Material : HSS M2;M35;ASP 2030

Dovetail Cutters

Product Code: MXCMC 12

Material : HSS M2;M35;ASP 2030

Serration Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

Circular Segmental Saws

We produce segmental circular saw blades in diameters from 250 mm to 1610 mm in various tooth profiles.

Hacksaw Milling Cutters

Product Code: MXHSMC 09

Material : HSS M2;M35;ASP 2030

Coatings available on request

End Mills Cutters

Product Code: MXCMC 11

Material : HSS M2;M35;ASP 2030

T-Slot Milling Cutters

Product Code: MXCMC 13

Material : HSS M2;M35;ASP 2030

Coatings available on request

Reamers

Product Code: MXR 22

Slitter Cutters

Available in D2,D3,HSS,H11,H13

Reamers

Product Code: MXR 22

Slitter Cutters

Available in D2,D3,HSS,H11,H13

Shell End Mills

Product Code: MXCMC 08

Material : HSS M2;M35;ASP 2030

Coatings available on request

ANGLE MILLING CUTTERS

Product Code: MXCMC 07

Material : HSS M2;M35;ASP 2030

Side & Face Milling Cutters

Product Code : MXCMC 06

Material : HSS M2;M35;ASP 2030

Coatings available on request

CORNER ROUNDING CUTTERS

Product Code : MXCMC 06

Material : HSS M2;M35;ASP 2030

Convex Milling Cutters

Product Code: MXCMC 05

Material : HSS M2;M35;ASP 2030

Sprocket Milling cutters

Product Code: MXSMC 15

Material : HSS M2;M35;ASP 2030

Gear Shaper Cutters

Product Code : MXGSC 17

Concave Milling Cutters

Product Code: MXCMC 06

Material : HSS M2;M35;ASP 2030