Maximizing Efficiency with Shell End Mills Cutting Tools

In the world of precision machining, the right tools can make all the difference. One of the most essential tools in the arsenal of any machinist is the shell end mill cutting tool. Known for its versatility and efficiency, the shell end mill is a cornerstone in...

Bandsaw Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

What is Gear Hobbing?

For high or low-volume production of external cylindrical gears, the industry frequently uses the continuous gear creation technique known as hobbing. One of the main manufacturing techniques used in the sector is gear hobbing. The requirements for additional gearing...

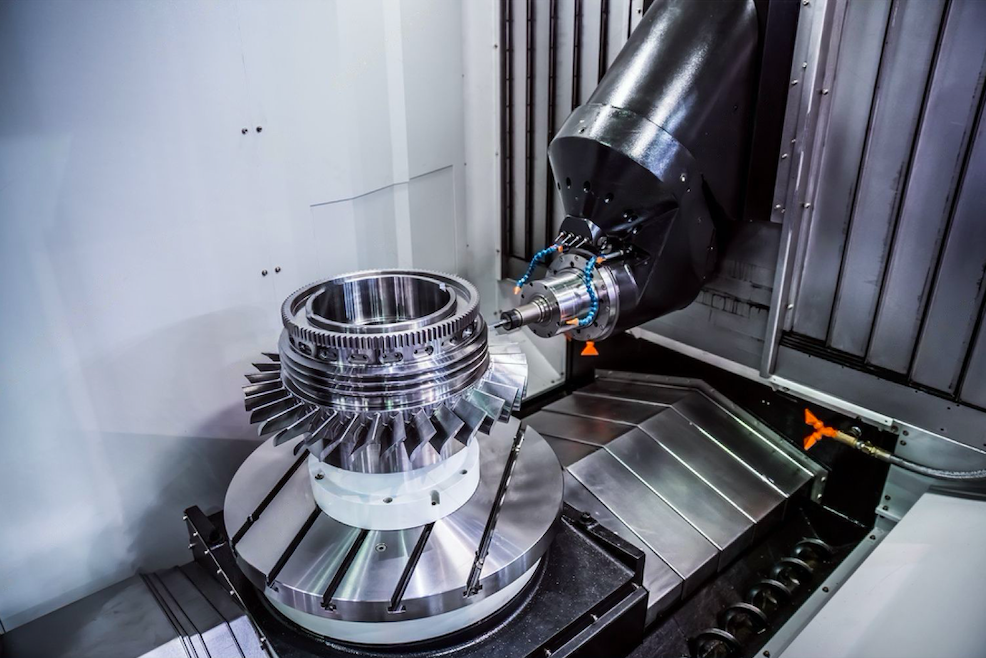

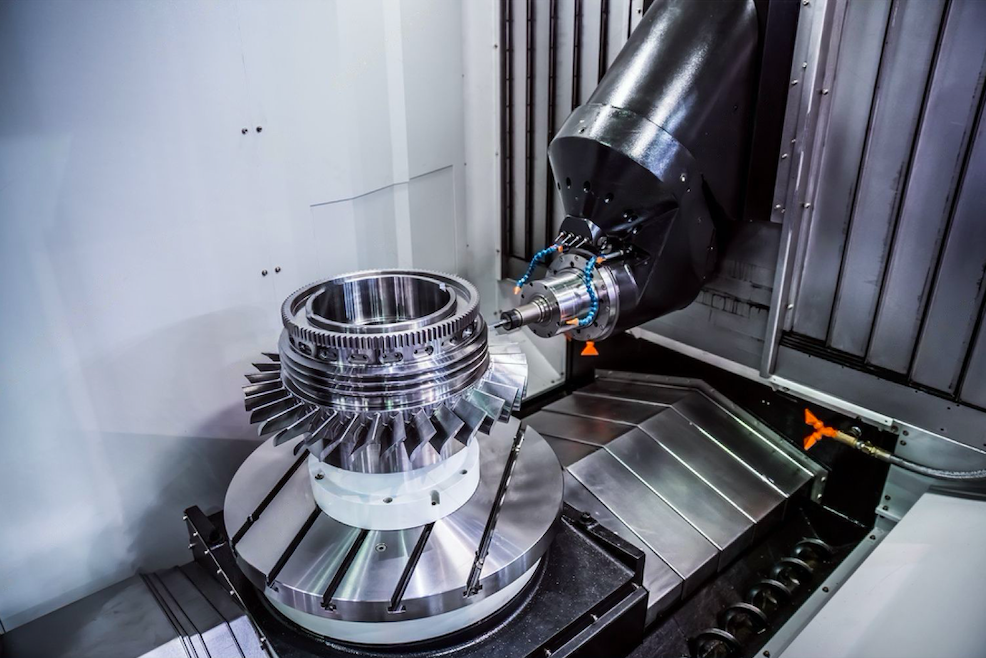

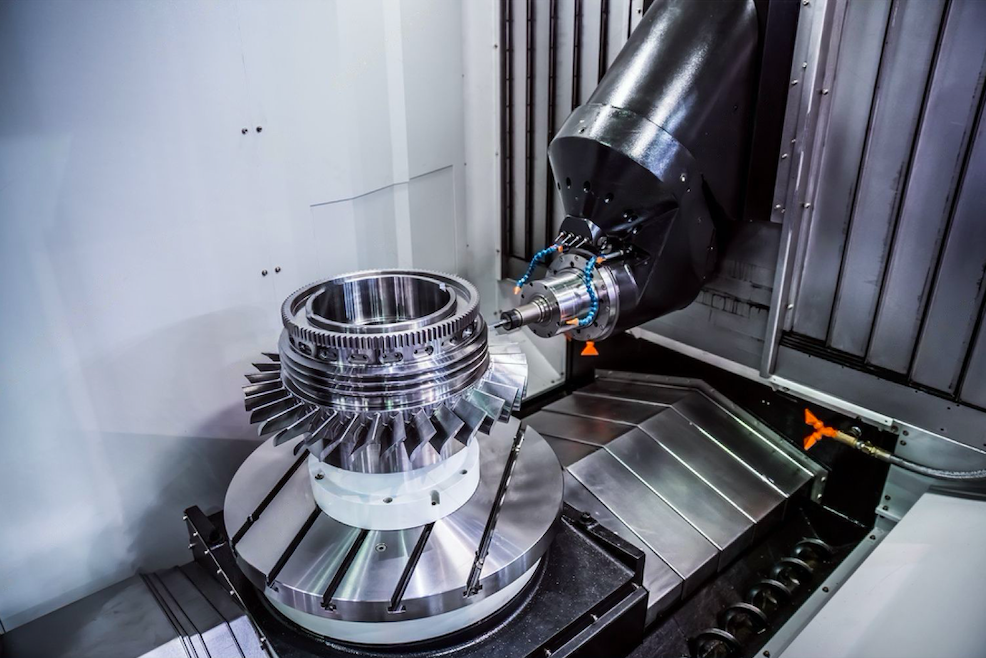

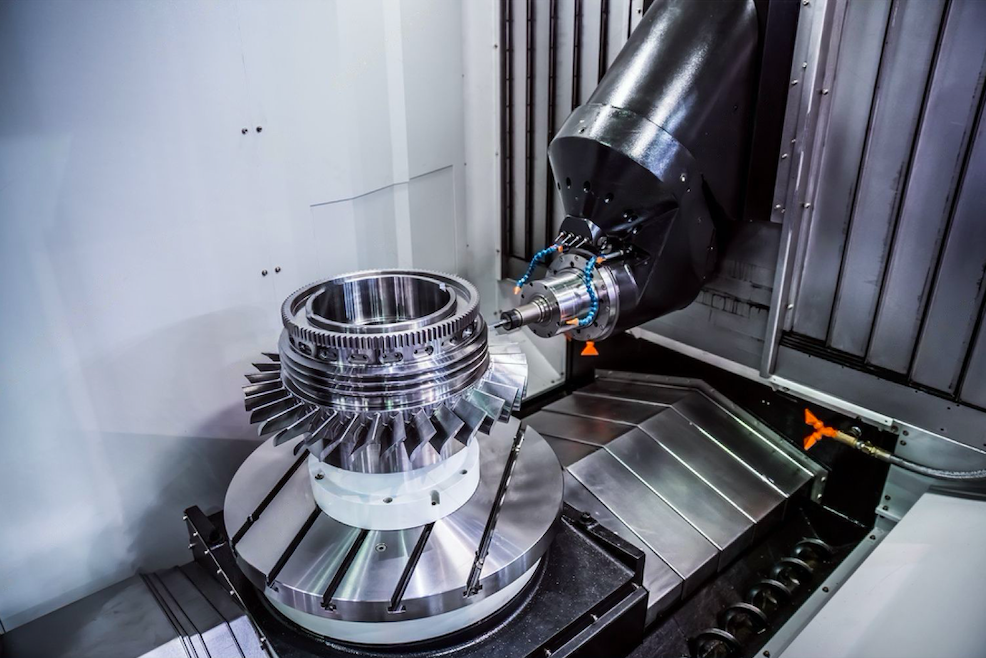

Milling Machine

Definition The workpiece is fed past a spinning multipoint cutter on a milling machine, which removes material from the workpiece. Due to the cutter's high speed and numerous cutting blades, the rate of metal removal is significantly higher. The fact that almost all...

SCALPING CUTTERS

Maxwell can proudly say that they hold a monopoly on Scalping cutter. Maxwell tools is the only supplier in the industry capable of manufacturing clear up to 1600mm OAL milling cutters.

Maximizing Efficiency with Shell End Mills Cutting Tools

In the world of precision machining, the right tools can make all the difference. One of the most essential tools in the arsenal of any machinist is the shell end mill cutting tool. Known for its versatility and efficiency, the shell end mill is a cornerstone in...

Bandsaw Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

What is Gear Hobbing?

For high or low-volume production of external cylindrical gears, the industry frequently uses the continuous gear creation technique known as hobbing. One of the main manufacturing techniques used in the sector is gear hobbing. The requirements for additional gearing...

Milling Machine

Definition The workpiece is fed past a spinning multipoint cutter on a milling machine, which removes material from the workpiece. Due to the cutter's high speed and numerous cutting blades, the rate of metal removal is significantly higher. The fact that almost all...

SCALPING CUTTERS

Maxwell can proudly say that they hold a monopoly on Scalping cutter. Maxwell tools is the only supplier in the industry capable of manufacturing clear up to 1600mm OAL milling cutters.

CONVEX MILLING CUTTERS

Milling cutters are manufactured using the latest and superior alloy steels and grade steel that provides high working hardness for about 600 degrees centigrade working conditions.

Slitting Cutters

Rotary Slitter Knives Maxwell manufactures slitter knives for all machine types: Maxwell manufactures slitter knives for all machine types: Adherence to the smallest possible thickness tolerance down to ± 2 microns. Subdivision of thickness tolerance in 3 areas (-,...

Hacksaw/Bandsaw Milling Cutters

Hacksaw milling cutters produced in high speed steels in a wide variety of diameters and lengths according to the application and machine. Our cutters are utilised to machine all types of bandsaw forms including vari-pitch, hook and positive rake. We produce hacksaw...

Maximizing Efficiency with Shell End Mills Cutting Tools

In the world of precision machining, the right tools can make all the difference. One of the most essential tools in the arsenal of any machinist is the shell end mill cutting tool. Known for its versatility and efficiency, the shell end mill is a cornerstone in...

Bandsaw Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

What is Gear Hobbing?

For high or low-volume production of external cylindrical gears, the industry frequently uses the continuous gear creation technique known as hobbing. One of the main manufacturing techniques used in the sector is gear hobbing. The requirements for additional gearing...

Milling Machine

Definition The workpiece is fed past a spinning multipoint cutter on a milling machine, which removes material from the workpiece. Due to the cutter's high speed and numerous cutting blades, the rate of metal removal is significantly higher. The fact that almost all...

SCALPING CUTTERS

Maxwell can proudly say that they hold a monopoly on Scalping cutter. Maxwell tools is the only supplier in the industry capable of manufacturing clear up to 1600mm OAL milling cutters.

CONVEX MILLING CUTTERS

Milling cutters are manufactured using the latest and superior alloy steels and grade steel that provides high working hardness for about 600 degrees centigrade working conditions.

Maximizing Efficiency with Shell End Mills Cutting Tools

In the world of precision machining, the right tools can make all the difference. One of the most essential tools in the arsenal of any machinist is the shell end mill cutting tool. Known for its versatility and efficiency, the shell end mill is a cornerstone in...

Bandsaw Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

What is Gear Hobbing?

For high or low-volume production of external cylindrical gears, the industry frequently uses the continuous gear creation technique known as hobbing. One of the main manufacturing techniques used in the sector is gear hobbing. The requirements for additional gearing...

Milling Machine

Definition The workpiece is fed past a spinning multipoint cutter on a milling machine, which removes material from the workpiece. Due to the cutter's high speed and numerous cutting blades, the rate of metal removal is significantly higher. The fact that almost all...

SCALPING CUTTERS

Maxwell can proudly say that they hold a monopoly on Scalping cutter. Maxwell tools is the only supplier in the industry capable of manufacturing clear up to 1600mm OAL milling cutters.

CONVEX MILLING CUTTERS

Milling cutters are manufactured using the latest and superior alloy steels and grade steel that provides high working hardness for about 600 degrees centigrade working conditions.

Slitting Cutters

Rotary Slitter Knives Maxwell manufactures slitter knives for all machine types: Maxwell manufactures slitter knives for all machine types: Adherence to the smallest possible thickness tolerance down to ± 2 microns. Subdivision of thickness tolerance in 3 areas (-,...

Hacksaw/Bandsaw Milling Cutters

Hacksaw milling cutters produced in high speed steels in a wide variety of diameters and lengths according to the application and machine. Our cutters are utilised to machine all types of bandsaw forms including vari-pitch, hook and positive rake. We produce hacksaw...

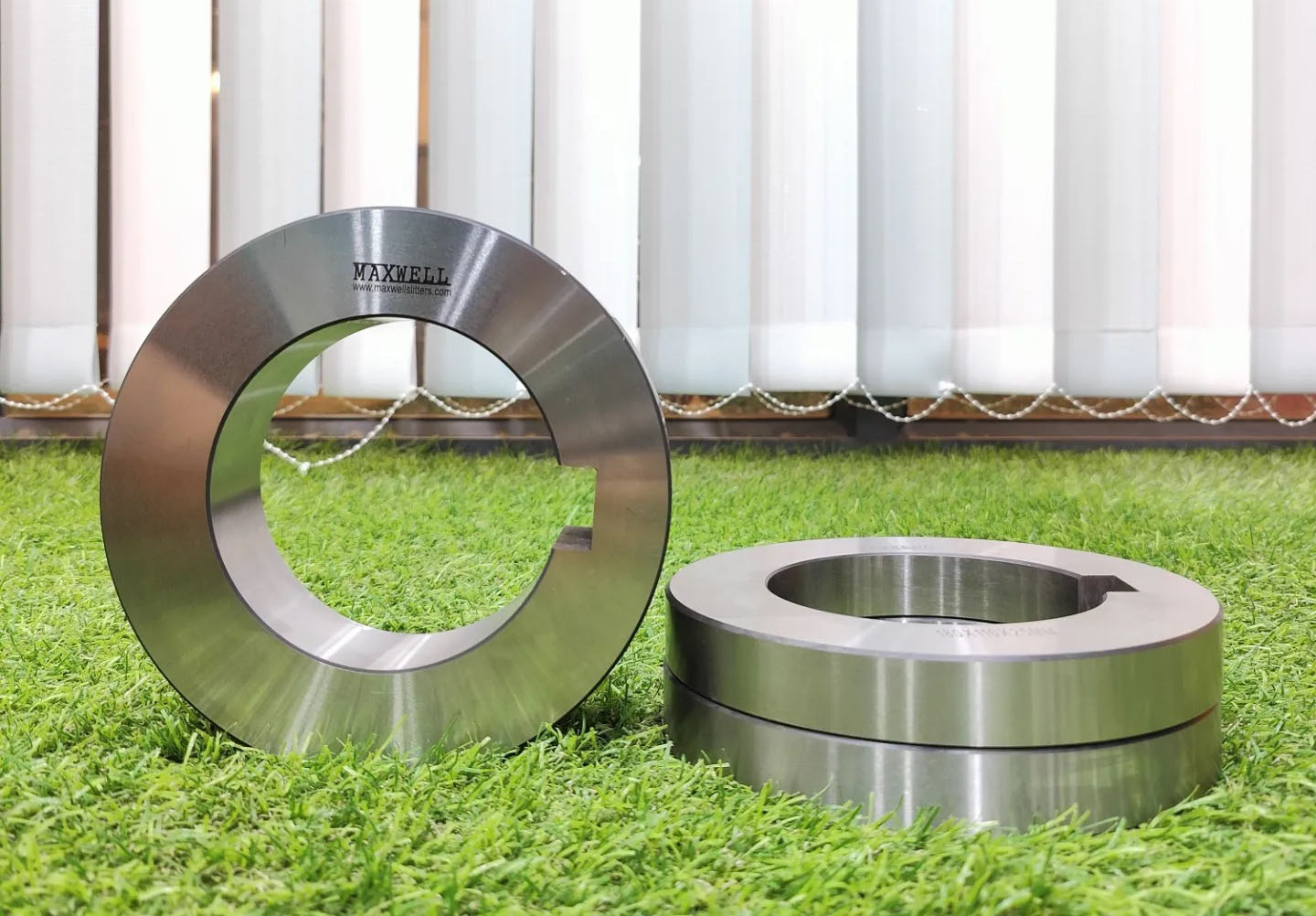

Slitter Spacers

Maxwell Slitting Line Spacers (Metallic & Rubberized) We manufacture a wide range of slitting line spacers (Metallic and Rubberized). These slitting spacers are widely used in different industries for cutting and trimming of different metals and alloys. We...

Maximizing Efficiency with Shell End Mills Cutting Tools

In the world of precision machining, the right tools can make all the difference. One of the most essential tools in the arsenal of any machinist is the shell end mill cutting tool. Known for its versatility and efficiency, the shell end mill is a cornerstone in...

Bandsaw Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

What is Gear Hobbing?

For high or low-volume production of external cylindrical gears, the industry frequently uses the continuous gear creation technique known as hobbing. One of the main manufacturing techniques used in the sector is gear hobbing. The requirements for additional gearing...

Milling Machine

Definition The workpiece is fed past a spinning multipoint cutter on a milling machine, which removes material from the workpiece. Due to the cutter's high speed and numerous cutting blades, the rate of metal removal is significantly higher. The fact that almost all...

SCALPING CUTTERS

Maxwell can proudly say that they hold a monopoly on Scalping cutter. Maxwell tools is the only supplier in the industry capable of manufacturing clear up to 1600mm OAL milling cutters.

CONVEX MILLING CUTTERS

Milling cutters are manufactured using the latest and superior alloy steels and grade steel that provides high working hardness for about 600 degrees centigrade working conditions.

Slitting Cutters

Rotary Slitter Knives Maxwell manufactures slitter knives for all machine types: Maxwell manufactures slitter knives for all machine types: Adherence to the smallest possible thickness tolerance down to ± 2 microns. Subdivision of thickness tolerance in 3 areas (-,...

Hacksaw/Bandsaw Milling Cutters

Hacksaw milling cutters produced in high speed steels in a wide variety of diameters and lengths according to the application and machine. Our cutters are utilised to machine all types of bandsaw forms including vari-pitch, hook and positive rake. We produce hacksaw...

Maximizing Efficiency with Shell End Mills Cutting Tools

In the world of precision machining, the right tools can make all the difference. One of the most essential tools in the arsenal of any machinist is the shell end mill cutting tool. Known for its versatility and efficiency, the shell end mill is a cornerstone in...

Bandsaw Milling Cutters

Product Code: MXHSMC 10

Material : HSS M2;M35;ASP 2030

Coatings available on request

What is Gear Hobbing?

For high or low-volume production of external cylindrical gears, the industry frequently uses the continuous gear creation technique known as hobbing. One of the main manufacturing techniques used in the sector is gear hobbing. The requirements for additional gearing...

Milling Machine

Definition The workpiece is fed past a spinning multipoint cutter on a milling machine, which removes material from the workpiece. Due to the cutter's high speed and numerous cutting blades, the rate of metal removal is significantly higher. The fact that almost all...

SCALPING CUTTERS

Maxwell can proudly say that they hold a monopoly on Scalping cutter. Maxwell tools is the only supplier in the industry capable of manufacturing clear up to 1600mm OAL milling cutters.

CONVEX MILLING CUTTERS

Milling cutters are manufactured using the latest and superior alloy steels and grade steel that provides high working hardness for about 600 degrees centigrade working conditions.

Slitting Cutters

Rotary Slitter Knives Maxwell manufactures slitter knives for all machine types: Maxwell manufactures slitter knives for all machine types: Adherence to the smallest possible thickness tolerance down to ± 2 microns. Subdivision of thickness tolerance in 3 areas (-,...

Hacksaw/Bandsaw Milling Cutters

Hacksaw milling cutters produced in high speed steels in a wide variety of diameters and lengths according to the application and machine. Our cutters are utilised to machine all types of bandsaw forms including vari-pitch, hook and positive rake. We produce hacksaw...

Slitter Spacers

Maxwell Slitting Line Spacers (Metallic & Rubberized) We manufacture a wide range of slitting line spacers (Metallic and Rubberized). These slitting spacers are widely used in different industries for cutting and trimming of different metals and alloys. We...

Shaving Cutters

After hob or shaper cutter processing, shaving cutters are used to remove very small portions of the gear tooth surface. After hob or shaper cutter processingGear Shaving operation fixes errors in the index, helical angle, tooth shape, and eccentricity. Additionally,...